Overview:

The Lithography and Print Finishing workshop at LCC contains many different machines which all have very specific uses. However, all of the printers in these areas use plates and take time to set up and operate, meaning that, while time-consuming and slightly more expensive, they can produce effects and colors which are impossible to achieve on a digital printer.

Notes:

Basic Information

- Print and Type Department

- Includes

- Machine-based print finishing

- Lithograph printing

- Risograph printing

- Letterpress

- Hand-done bookbinding

- Includes

- Print Finishing

- Can be for anything at all

- Posters

- Books

- Magazines

- Business cards

- Can be for anything at all

- Labeling System

- Green -> Anyone can use

- Yellow -> Use after induction

- Red -> Only use with a technician

- The Importance of Bleed

- Bleed is 3mm around the printed object

- Image MUST reach past that line

- Critical to printing and one of the most common mistakes

Equipment in the Finishing Room

| In-Line Stitch Machine | Lightbox | Speed or Strip Binder |

| Stab Stitch Machine | Saddle-Stitch Machine (wire thread) | Folding Machine |

| Drill | Board Cutter | Guillotine |

| Perfect Binding Machine | Perfect Binding by Hand | Nipping Press |

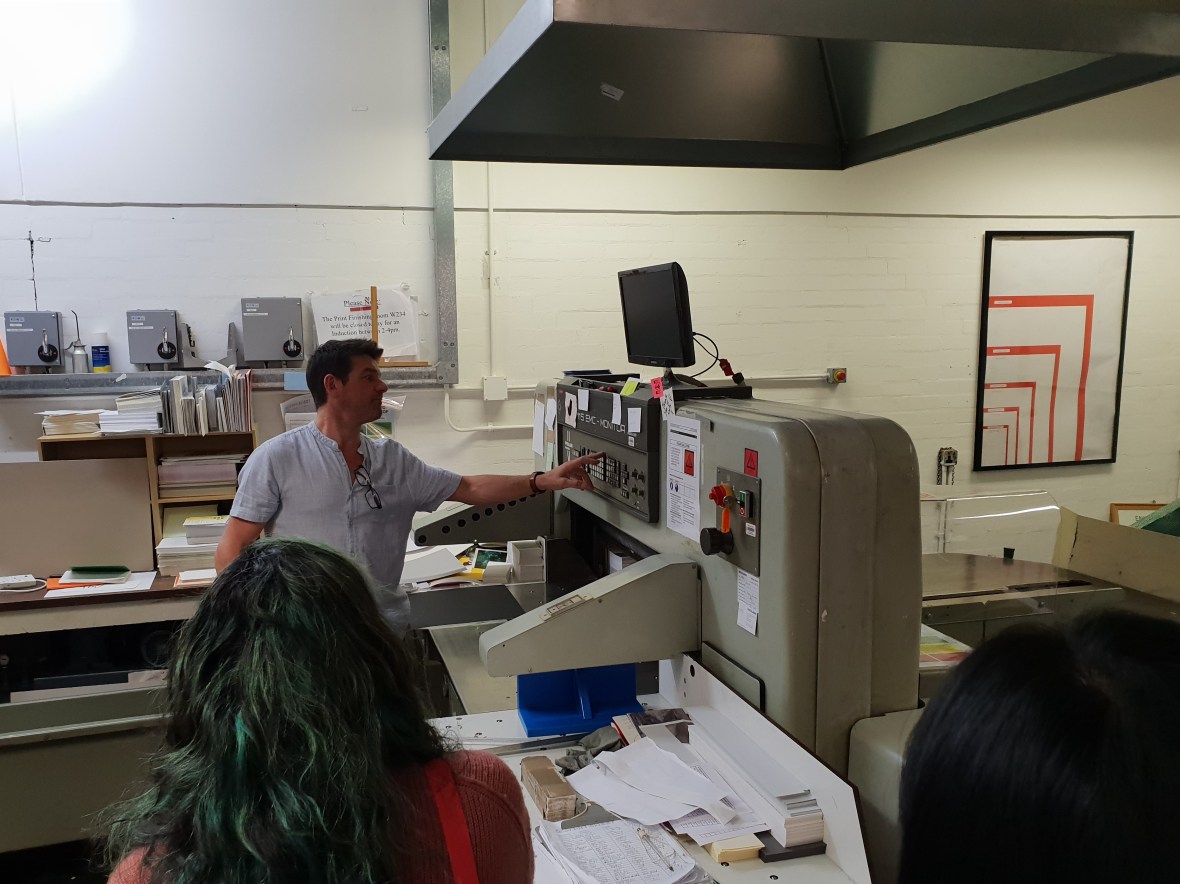

- The Guillotine

- Creases and cuts in huge amounts of paper

- Works according to exact measurements

- There are safety precautions built in

- To use, press down on the foot pedal and press both buttons simultaneously

Different Kinds of Binding

| Perfect | Saddle Stitch | Stab Stitch |

| In-Line | Spiral | Strip |

Folding and Creasing

- Folding is done with a knife and machine, as large pages are fed in, folded, perforated, and ejected from the other side

- Capacity crease

- Stretches, instead of breaks the paper’s fibres and stops ink from cracking

Equipment in the Printing Room

- Risograph Printer

- Plates cost 1 pound each

- Low quality

- Cheap prints

- Platemaker

- Plates cost 10 pounds each

- Special aluminum plate is wrapped around a cylinder and the image is exposed onto this plate by the machine

- Makes use of pre-flight software to do screen-checks before creating the plate

- Makes sure resolution, format, and everything else is in order

- Makes plates for the lithograph printers, like the offset press

- Epsom Printers

- Can print on two sides

- Can print on your own paper and substrate

- Substrate can be thick

- Flat-Bed Press

- Based on a motion of cylinders

- The cylinder rolls over the substrate

- You can print on any flat substrate

- Glass

- Cardboard

- Paper

- Thermo

- Heats powder placed on wet ink and creates a shimmer

- Only works on a project which has not been printed digitally

- Very good for letterpress, screenprinting, and risograph

- Offset Lithography Printer

- Works on a principle of cylinders and images which are “offset”, meaning the substate never touches the actual plate

- You are able to print a wide array of colors which are impossible to fully replicate digitally

- Can also use spot colors

- You are also able to print in metallic colors

- Four-Color Press

- Prints many copies very fast

- Usually intended for mass production

- The printer prints black, then blue, then red, then yellow in the CMYK color scheme

- The K stands for black because it is the “key” color

- Prints many copies very fast

Classwork:

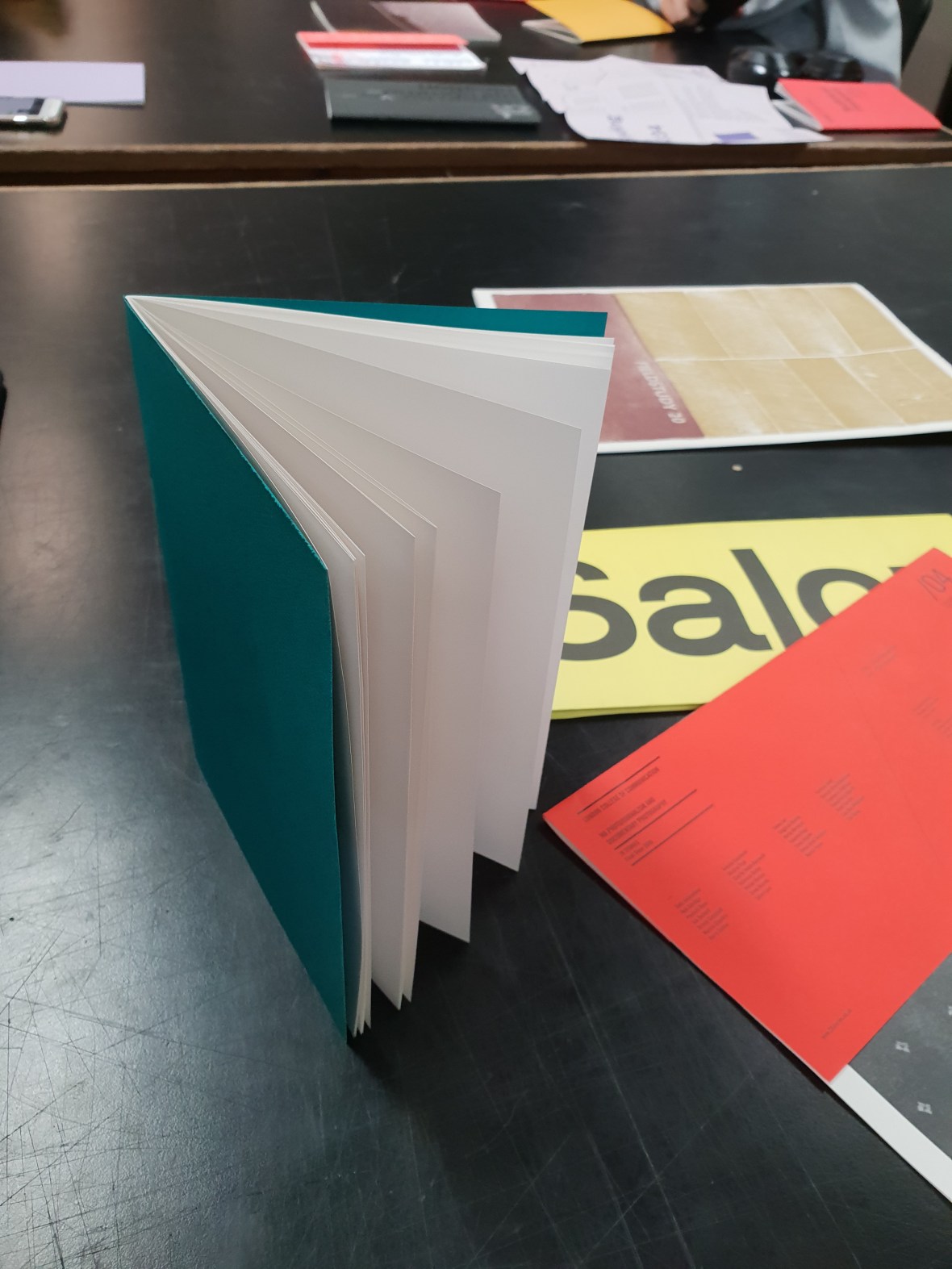

Creating a Booklet

- Folding the paper

- Creasing the cover

- Saddle stitching the pages and cover together

- Using the guillotine to cut down the pages