Procedure and Class Notes

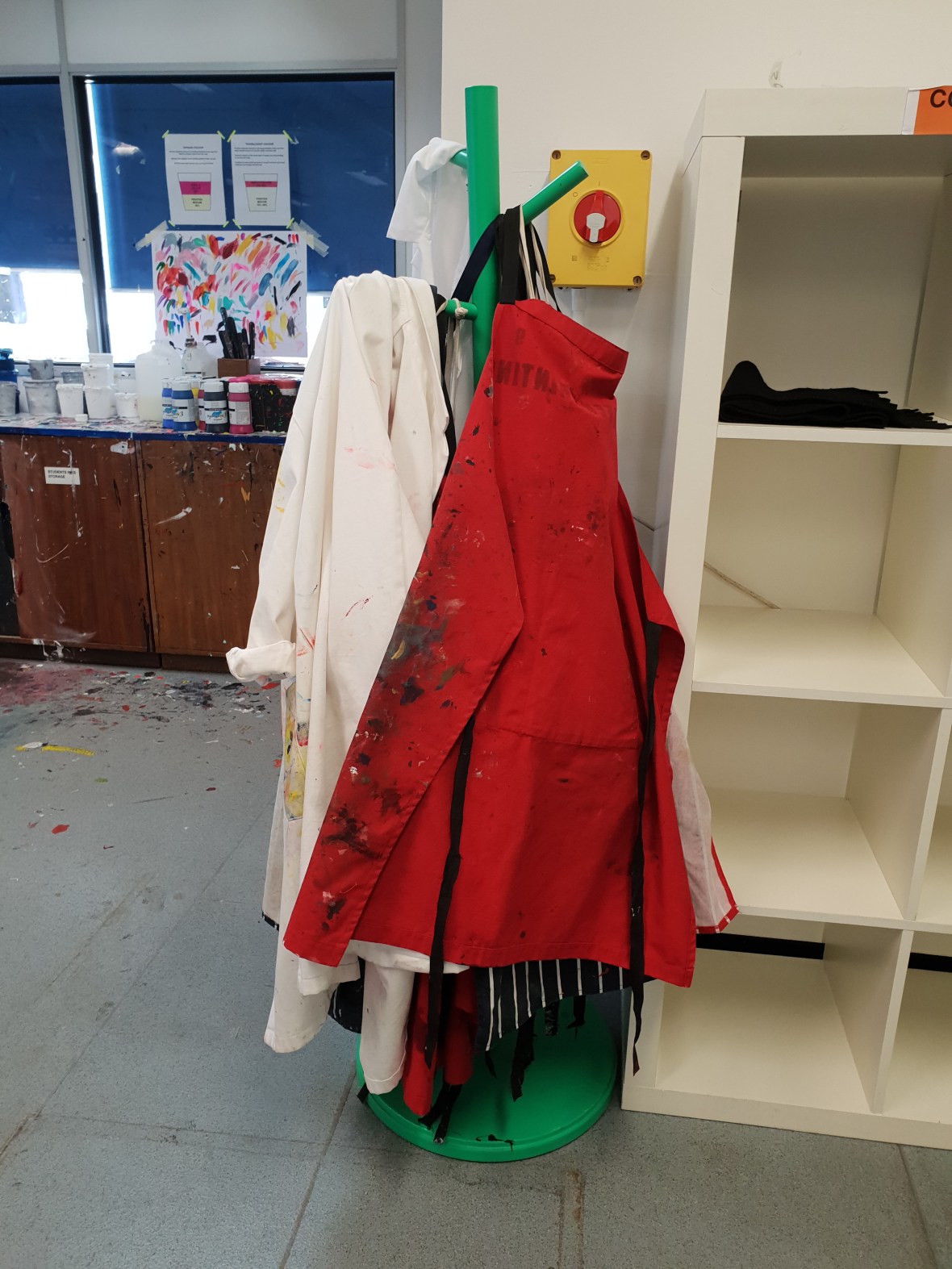

Health and Safety

- Sensible footwear

- No open toes

- No open heels

- No slippers

- No drinks or food

- Long hair has to be tied

- Lanyard tucked in

- Don’t wear nice clothes

- Wear aprons

Printing with the Screen

- You can print on anything flat

- Screenprinting is done in layers, one color at a time

- However, you can end up with more colors on the sheet than you printed because of overlays and overlaps

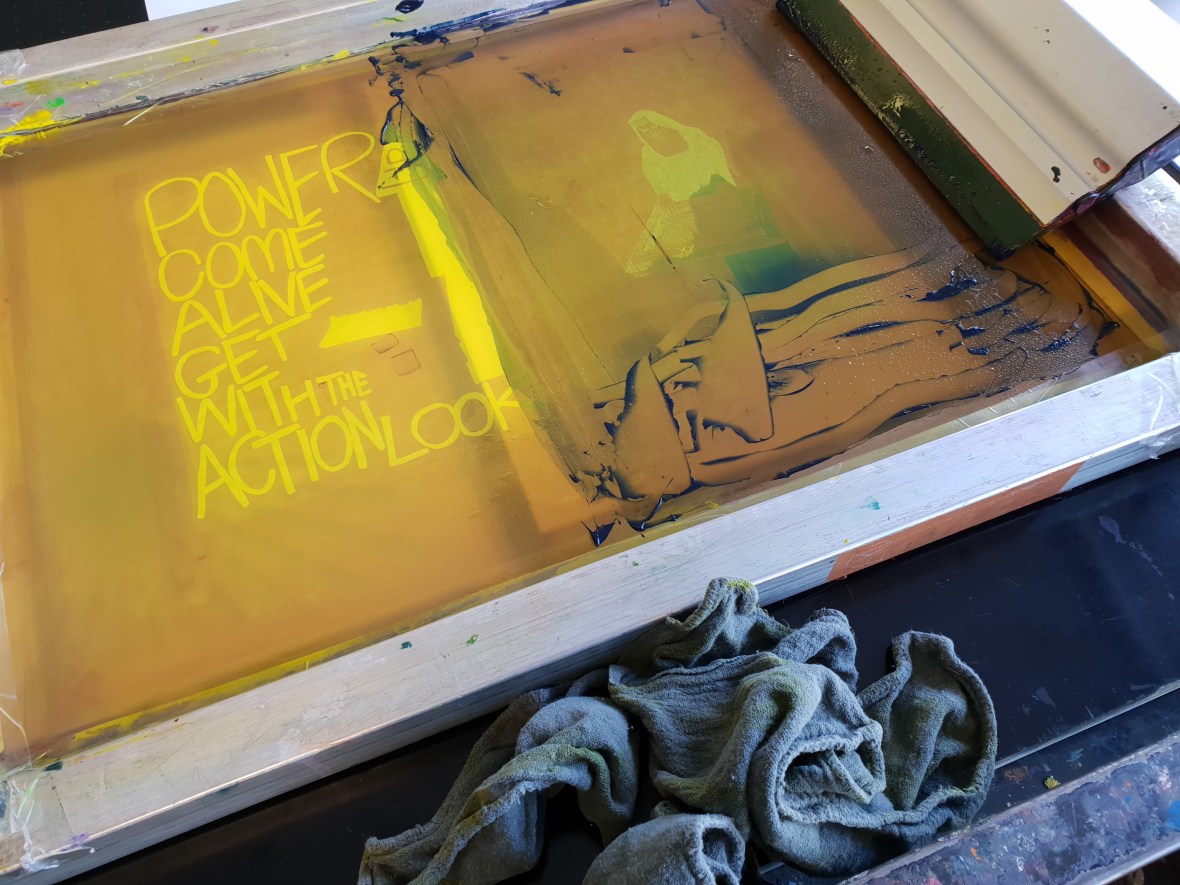

- Stencil-Based Process

- Can use paper to block off areas of the mesh to print

- Photographic stencils most commonly used

- Emulsion is exposed to UV light over the positive

- Emulsion hardens where the light shines through and remains soft where the positive is

- The un-hardened emulsion is washed off and the image remains in the screen mesh

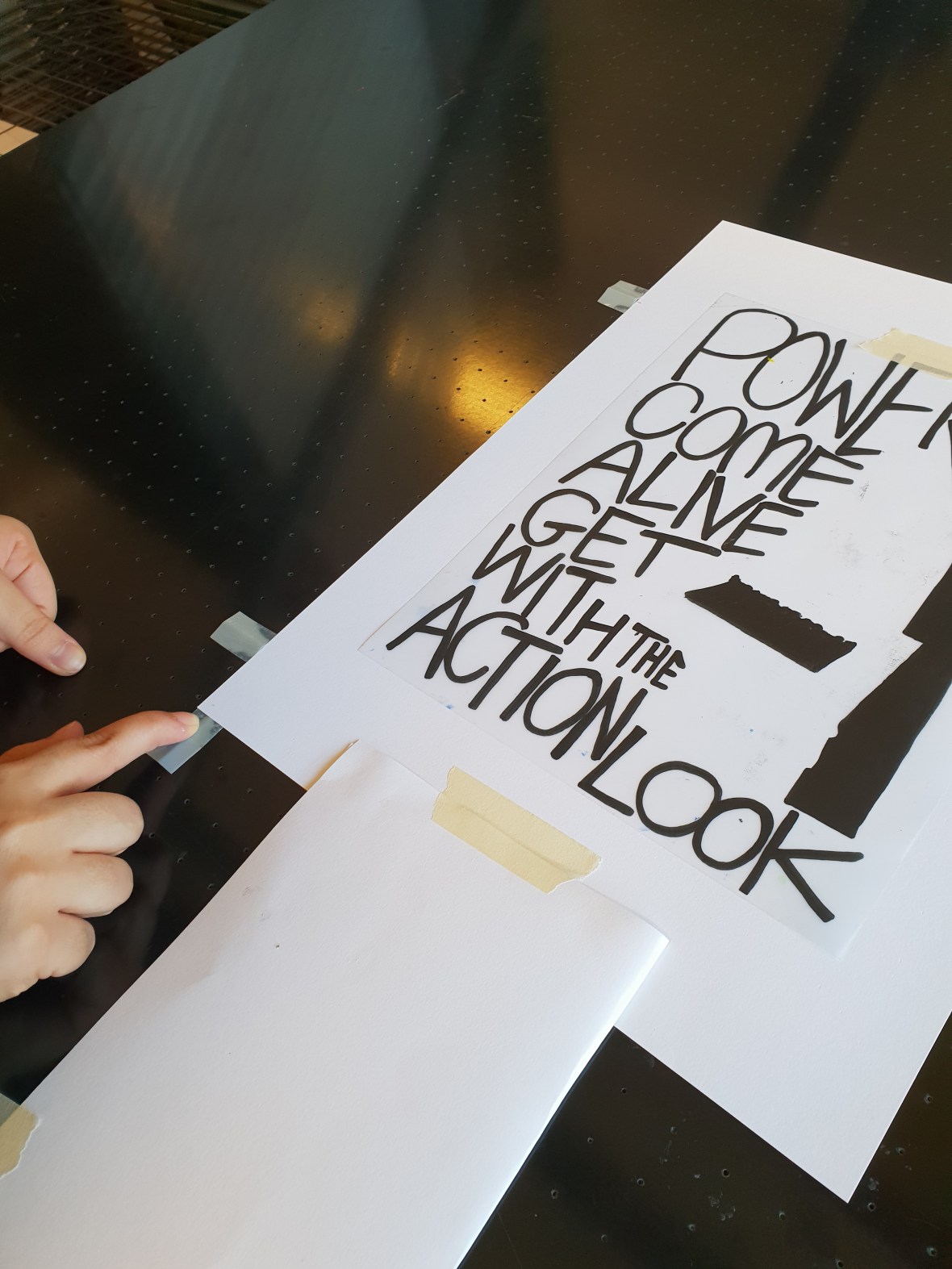

- Positives

- Image of what will be printed in different layers of color

- Can be done in many different ways

- Marker

- The Screen

- A screen is made up of a frame with mesh fabric

- The screen is fragile

- Always check for sharp objects

- When using scissors, always cut away from the screen

Ink

- The ink used for screen printing is water based

- Acrylic mixed with the printing medium

- Cannot print without it

- Without the medium, it is far too much

- Acrylic mixed with the printing medium

- Ink is free at LCC

- Unique inks

- Metallic

- Thermo

- Conductive

- Glow in the dark

- Mixing ink

- Place printing medium in the container first

- Doing this will prevent the ink from sticking to the side

- Use 50% or more medium per ink mix

- The more medium, the more transparent it is

- Use the spatula to stir the paint in

- Mix acrylic into the middle and move to the outside

- Test on both white paper and the same kind of paper you will be using for your project

- Gives you a better understanding of how it will turn out

- Place printing medium in the container first

- Ink is usually applied from lightest to darkest

- Sometimes this is the only way layering will work properly, but it depends on the color, paper, and projects

- If you want to print neon on black, do the print in white first and then lay it over on top

- Preparation is key

- Do not store ink on the table so it does not get on your project

- Store it below the table or next to you, but be careful of blank paper next to you

Steps

- Tape out the screen

- Stops the ink from going through the edges of the screen and onto the table

- Makes cleaning easier

- Procedure

- Stretch out tape longer than the screen

- Pull so the tape bends in half

- Put the tape down, half on the mesh and half on the frame

- Smooth down and create as few wrinkles as possible

- Preparing the Handbench

- Also known as screen bed

- Holds the screen while printing

- Holes in the bed act as a vacuum and suck the paper to the bed when printing

- Weights are attached to the back of the handbench and keep it up and down as necessary

- You must keep control over this so it does not snap back

- Handbenches also have a squeegee arm

- Allows you to apply even pressure on large substrates

- When leaving, always make sure to tighten the knobs and leave the handbench up

- Placing the Screen

- Open the side arm

- Place the screen flat on the table

- Position the screen and place it on the sidebar so there is a gap between the table and the screen

- This gap is called the “snap” because the screen literally “snaps” back to the original form after printing

- This is ALWAYS present when printing on hard surfaces, but NEVER present for textiles and soft surfaces

- Tighten the arm just enough to hold the screen

- Clamps click in place

- Positioning and Registration

- Position the positive where the print should be on the page

- Tape the positive in place

- Fold a piece of paper and attach it to the bottom of the paper (known as a “helpful arm”)

- Use the helpful arm to alight the page underneath the screen

- Tape the arm to the table

- Tape the paper to the table

- Position the positive where the print should be on the page

- Remove the arm and stick it to the side of the table for further use

- Align Lay Stops

-

- Place three tented lay stops on the corner and one side of the aligned print to mark where the paper needs to be for printing

- Called “3-point-registration”

- Only one side necessary because paper sizes vary slightly per individual page

- Mark where the middle of the tented lay stops fall on the page

- This helps if you want to return to the design

- The sheet which is marked up is called the “lay sheet” and it is the master copy

- Place three tented lay stops on the corner and one side of the aligned print to mark where the paper needs to be for printing

- Registration

- To register means to line up the different colors and screens so that the design falls correctly and the overlay colors print well

- Use lay stops and the helpful arm to do this

- Mask out the table

- Small pieces of tape on the outside and longer pieces of tape on the inside so the pages do not flutter

- Keeps the holes clean

- Covering the holes makes the suction stronger

- Do NOT cover the lay stops

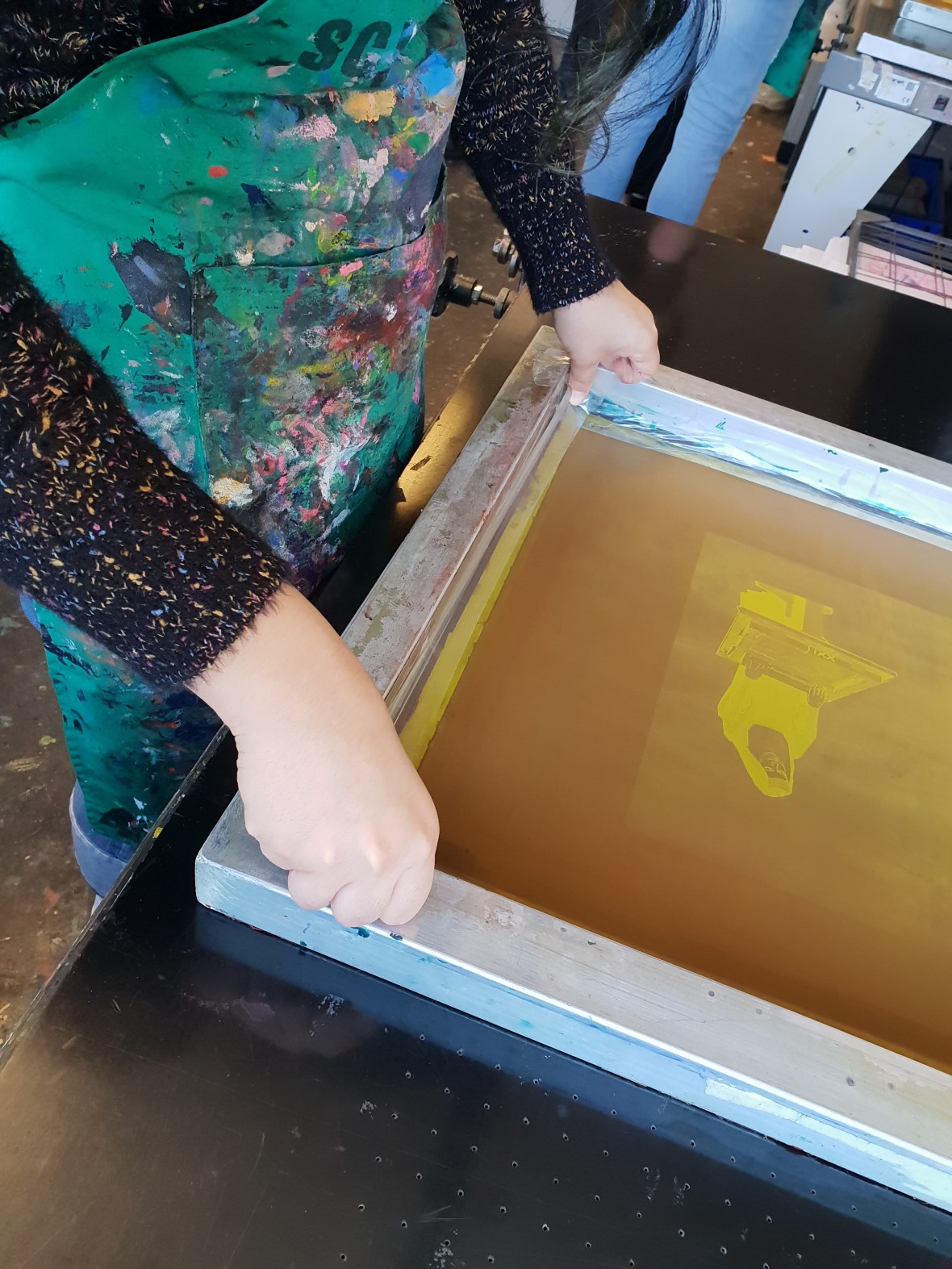

- Select your squeegee

- The squeegee is a handle with a rubber blade

- The purpose of a squeegee is that it pushes ink through the holes in the mesh

- Select a squeegee just slightly bigger than the image itself for full and even coverage

- Start printing

- The printer is the only one in charge of the machine at this point

- Turn the vacuum on to keep the paper in place

- It will automatically turn on and off because of an internal mechanism during the process

- Lower the handbench and lean it on your hip above the printing surface

- Flood the screen

- Place ink in the front and pull towards the back

- You don’t need to push down hard

- Always make sure there is fresh ink, otherwise, it will come out streaky or not at all

- Dries very quickly

- Cover the entire width of the squeegee

- One stroke back to flood and one stroke back to print

- Print

- Lower the handbench onto the table

- Pick up the squeegee from the back

- Press down with both hands and pull towards you

- When finished, flood again and place squeegee in screen

- Raise handbench and remove the print

- Keep the lay sheet

- Cleaning

- Cleaning is done in place on the table

- Scoop up ink with reusable plastic card

- After this, spray the screen with water

- Use rags and squeegee to push ink onto a scrap paper below

- Wash the bottom of the screen

- Dry with rag

- Additional printing parts

- Repeat above steps

- Use lay sheet to register

- Always print on lay sheet first for every layer

- Use the handy arm and positive to reposition

- Print again